In a laboratory settings, fume hoods play a pivotal role in ensuring the safety and well-being of researchers by effectively containing and eliminating hazardous fumes, gases, and airborne contaminants. However, the performance of a fume hood depends on various intricate factors that must be carefully considered to optimize its efficiency. Understanding these factors is crucial for researchers, safety officers, and laboratory personnel to maintain a safe working environment and uphold scientific integrity.

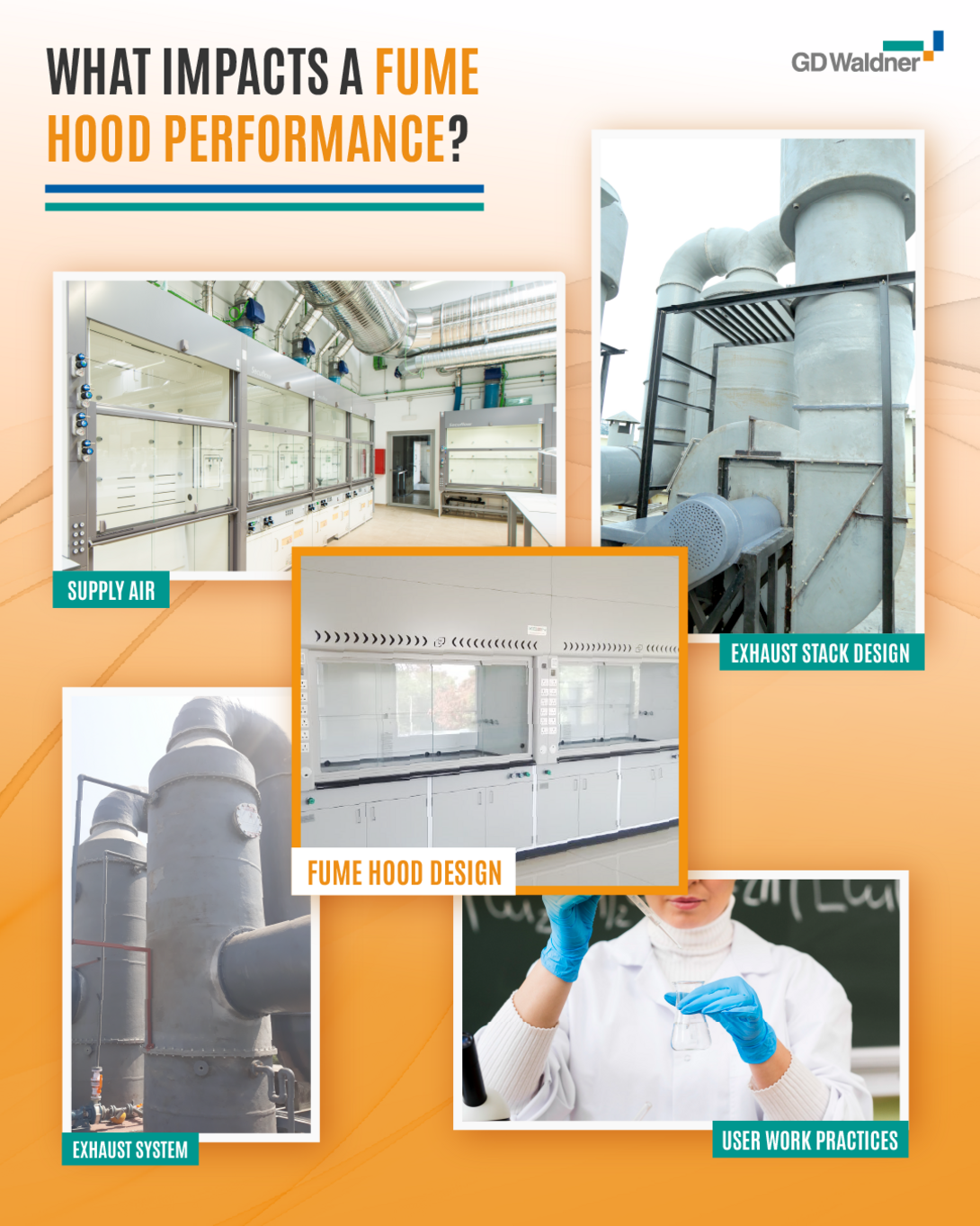

- Fume hood Design - An efficient fume hood design is crucial for safe and effective airflow. Proper aerodynamics, including an airfoil shape, streamlined sash handle, effective baffle arrangement, appropriately sized exhaust port, aerodynamic corner posts, and a well-designed bypass system, all play a significant role in ensuring smooth exhaust flow and preventing reverse flow towards the user. Neglecting these design elements can lead to hazardous consequences, emphasizing the criticality of a correctly designed fume hood.

- Supply Air - To maintain negative pressure within the laboratory, it is vital to have lower lab air supply compared to exhaust air. This is crucial for optimal fume hood performance. Positioning supply air diffusers at least 5 feet (1.5 meters) away from the fume hood sash plane helps minimize turbulence in the airflow. It is important to avoid directing the supply air towards the fume hood face to prevent increased fume leakage and hindered performance. Ensuring cross drafts within the room are below 30 fpm (0.15 m/s) and keeping ceiling fans away from the fume hood are essential to prevent disruptions in airflow and minimize potential leakages.

- Exhaust System- The fume hood exhaust blower can be likened to the heart, while the ductwork acts as the blood veins. Proper sizing of the blower and ductwork is crucial for a smooth flow. The blower's capacity directly affects the fume hood face velocity. Even small adjustments in damper positions within the ductwork, such as fume hood dampers, branch dampers, or bypass dampers, can impact the flow of the fume hood. In Variable Air Volume (VAV) systems, which involve electromechanical components, our experience indicates that these parts often experience wear and tear, resulting in failures within 3 to 5 years. Without a robust maintenance program in place, such failures can go unnoticed. Therefore, it is essential to implement comprehensive maintenance procedures to ensure the proper functioning of VAV systems.

- Exhaust Stack Design - A poorly designed exhaust stack can have detrimental effects, spreading fumes in the surrounding areas and potentially reintroducing chemical fumes back into the lab. This issue is prevalent in labs located in densely populated areas. To mitigate these risks, it is essential to adhere to local pollution control board regulations and use a sufficiently tall exhaust stack. A recommended minimum height is 10 feet (3 meters) above the building's roof level.

- User Work Practices - Fume hood performance and user safety are profoundly influenced by various factors, with one of the most crucial being user practices. Certain common incorrect practices can significantly impact fume hood airflow and compromise safety. These practices include loading lab equipment inside the hood, obstructing the airfoil and baffles, frequently keeping the sash open beyond the safe opening height, putting one's head inside the hood, and disregarding airflow alarms for low or high flow. Engaging in any of these actions undermines the hood's intended purpose and directly exposes the user to fumes.

With our expertise and commitment to innovation, we integrate advanced technologies and engineering principles into the fume hood solutions. By continuously improving the design, airflow management, and safety features, we ensure that the fume hoods meet the highest standards of performance, reliability, and user protection.